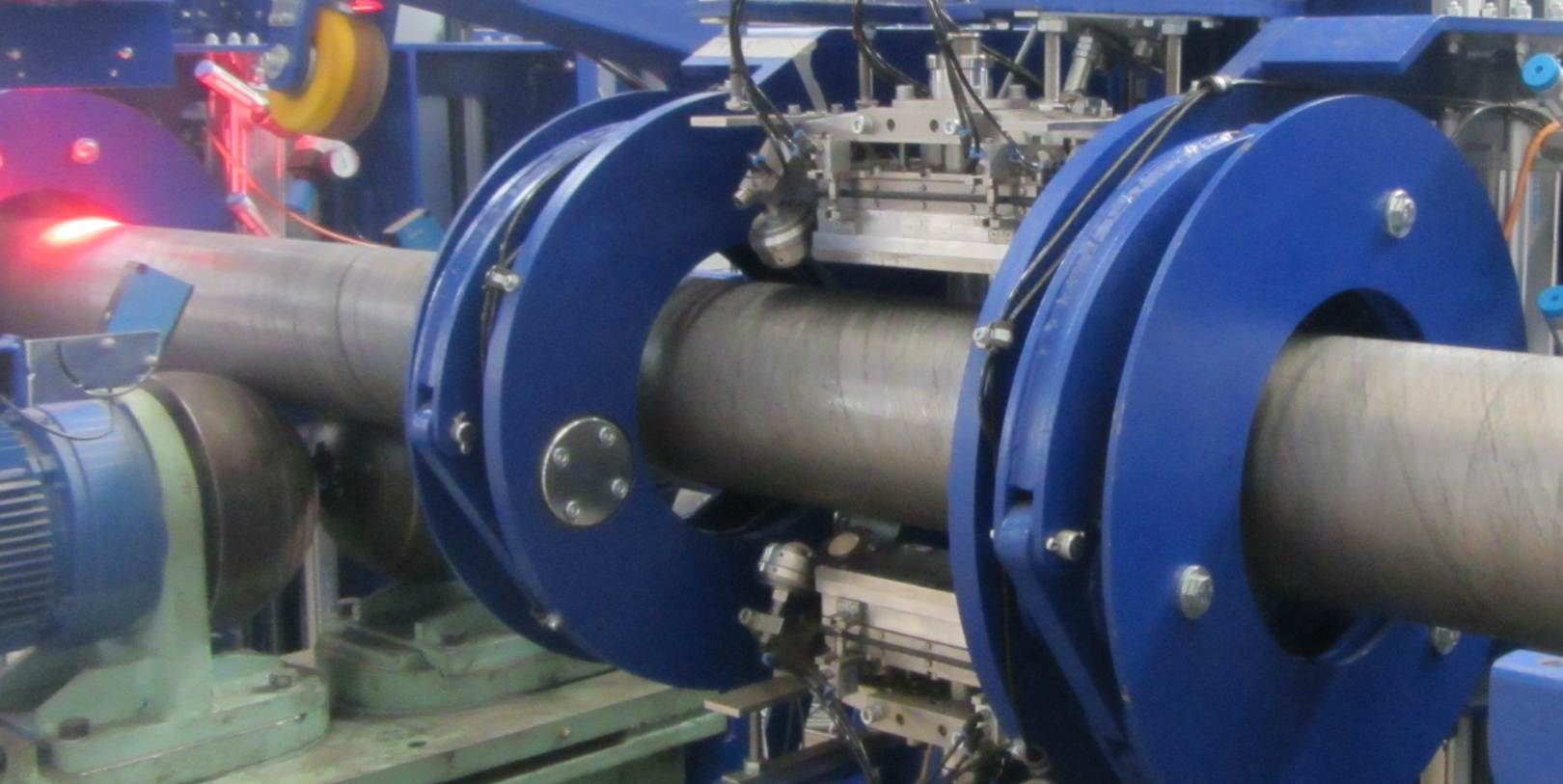

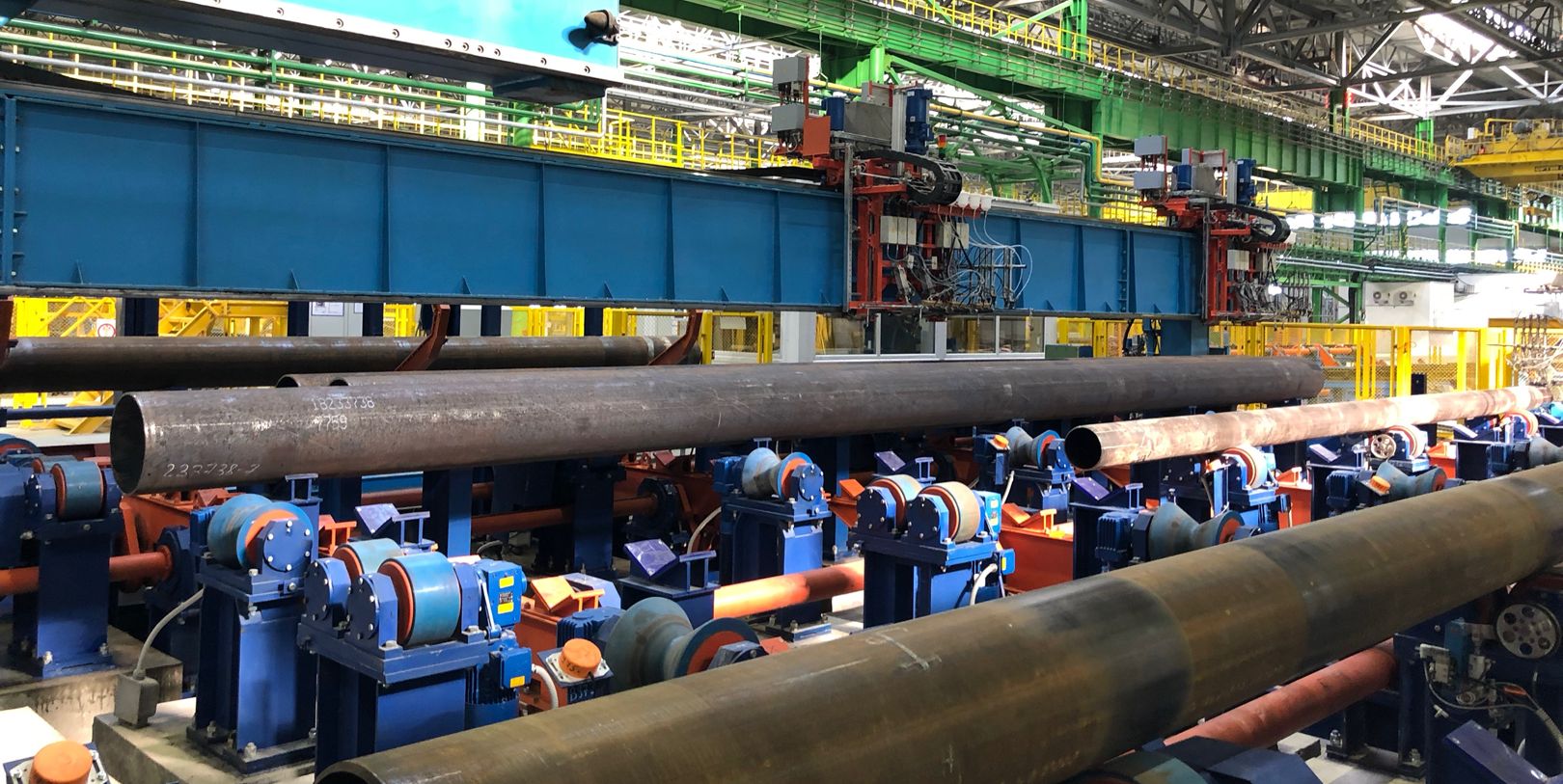

NORDISCAN-PI is our common platform for all Tube and Pipe inspection applications. Modular design allow the use of UT (Piezo), Phased Array, UT Arrays, Eddycurrent, and EMAT technology depending on the specific tasks needed for our clients. Nordinkraft has practical experience in development, design and implementation of complex equipment for automated ultrasonic testing of all types of tubes and pipes, from very large diameter to very small diameter welded products to seamless, cold drawn and centrifugally cast.

NORDISCAN-PI equipment can be used in the production line of any modern pipe plant and perform in-depth and effective ultrasonic inspection of Weld zones and HAZ, Pipe Ends, Full Body inspection, surface and subsurface, ID and OD, ovality and thickness. Additionally, we offer our NORDISCAN-PL plate inspection system to inspect Skelp prior to welding for laminations and edge inspection to ensure the weld zone is of high quality. Finally, we offer our EMATEST-WSP scarf removal and monitoring tool to ensure ID and OD weld scarfing process is functioning correctly and eliminates waste by detecting a broken scarf removal tool quickly and accurately.

NORDISCAN-PI is our common platform for all Tube and Pipe inspection applications. Modular design allow the use of UT (Piezo), Phased Array, UT Arrays, Eddycurrent, and EMAT technology depending on the specific tasks needed for our clients. Nordinkraft has practical experience in development, design and implementation of complex equipment for automated ultrasonic testing of all types of tubes and pipes, from very large diameter to very small diameter welded products to seamless, cold drawn and centrifugally cast.

NORDISCAN-PI equipment can be used in the production line of any modern pipe plant and perform in-depth and effective ultrasonic inspection of Weld zones and HAZ, Pipe Ends, Full Body inspection, surface and subsurface, ID and OD, ovality and thickness. Additionally, we offer our NORDISCAN-PL plate inspection system to inspect Skelp prior to welding for laminations and edge inspection to ensure the weld zone is of high quality. Finally, we offer our EMATEST-WSP scarf removal and monitoring tool to ensure ID and OD weld scarfing process is functioning correctly and eliminates waste by detecting a broken scarf removal tool quickly and accurately.

The NORDISCAN-PI series addresses multiple inspection tasks:

- Examination of Pipe body;

- Examination of Both Pipe Ends;

- Examination of Weld Seam and HAZ;

- ID, OD, Mid wall and surface Examination;

- Wall thickness measurement;

- Weld Seam profiling and Scarfing Quality Monitoring.

Typical Specification of Pipes to be Tested:

- Type or Pipes to be Tested:

- Seamless, ERW, Line Pipes (LSAW, HSAW);

- Diameters: 10 mm – 1520 mm;

- Thickness: 0.4 mm – 60 mm;

- Material: carbon steel, stainless steel, aluminum, titanium, cooper and alloys.

Type of Applied Multichannel Ultrasonic or Eddy Current probes:

- Non-contact array probes, based on the EMAT;

- UT phase array probes;

- UT probes with the array of piezo-crystals;

- Eddy-current probes;

- Weld seam tracking, visual, video.

Ultrasonic Testing Standards:

Density of Ultrasonic examination, test procedures, acceptance criteria, data processing and representation adhere to multiple international and local standards such as: GOST-R 52079-2003; API Spec 5CT (Ed. 9), ISO 11960 2004, API 5L (Ed. 44,2008); ISO 3183; GOST 10705-80; GOST 20295-85; GOST R 52079-2003; GOST R 53366 2009; ISO 9303; ASTM E213, etc.

Testing and acceptance criteria can be customized based on client specific needs and new standards.